EDUCATION • DIGITAL FABRICATION

Nimble Animation Stand

A simple and open-access digital fabrication design for a portable multiplane animation stand. This project with the Animate Materials Workshop called for designing, testing, and fabricating a portable multiplane animation stand for artists with any level of animation experience to create temporary animation setups in a variety of locations, being ideal for artists who don't have a dedicated studio space or those who want to try fieldwork animation outdoors.

In collaboration with

Background

Traditional under-the-camera animation stands are large, expensive, and difficult to move. DIY solutions, while more accessible, are often bulky, rigid, and hard to disassemble or reconfigure.

To make multiplane animation more accessible and mobile, the Animate Materials Workshop developed the nimble multiplane—an open-access prototype that can be built in a local digital fabrication lab or makerspace.

The Challenge

To design an accessible, user-friendly, and modular multiplane animation stand that can be manufactured in a local makerspace, offering artists an easy-to-assemble, highly portable setup for both studio and outdoor shooting, thus lowering the barrier to entry for multiplane animation.

DESIGN QUESTION

How might we design an easy-to-assemble, modular, and portable multiplane animation stand that is easy to assemble and requires minimal hardware, reducing the cost and complexity barrier to entry for independent animators to expand the possibilities for mobile and non-traditional stop-motion and material animation?

Design Process

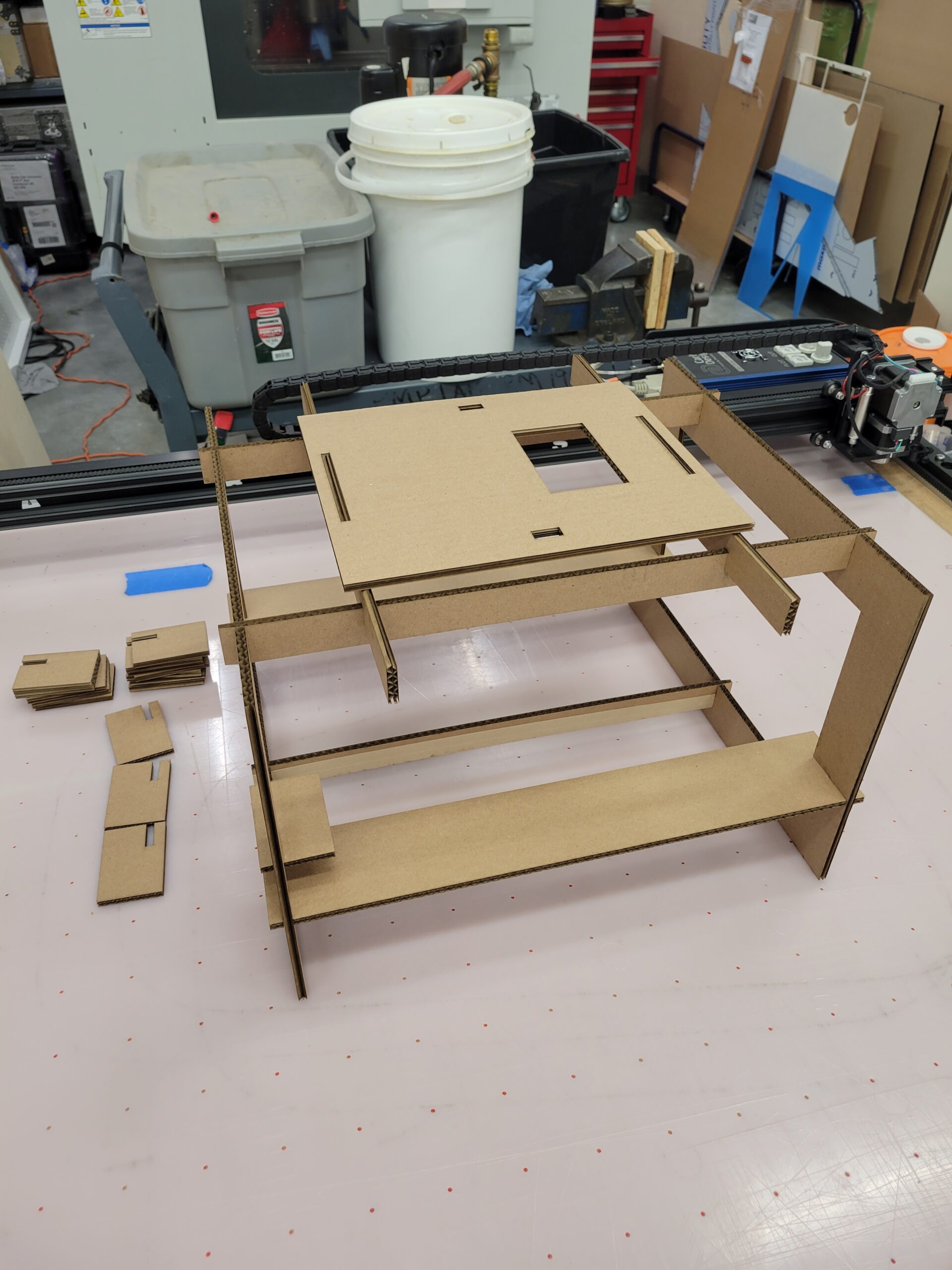

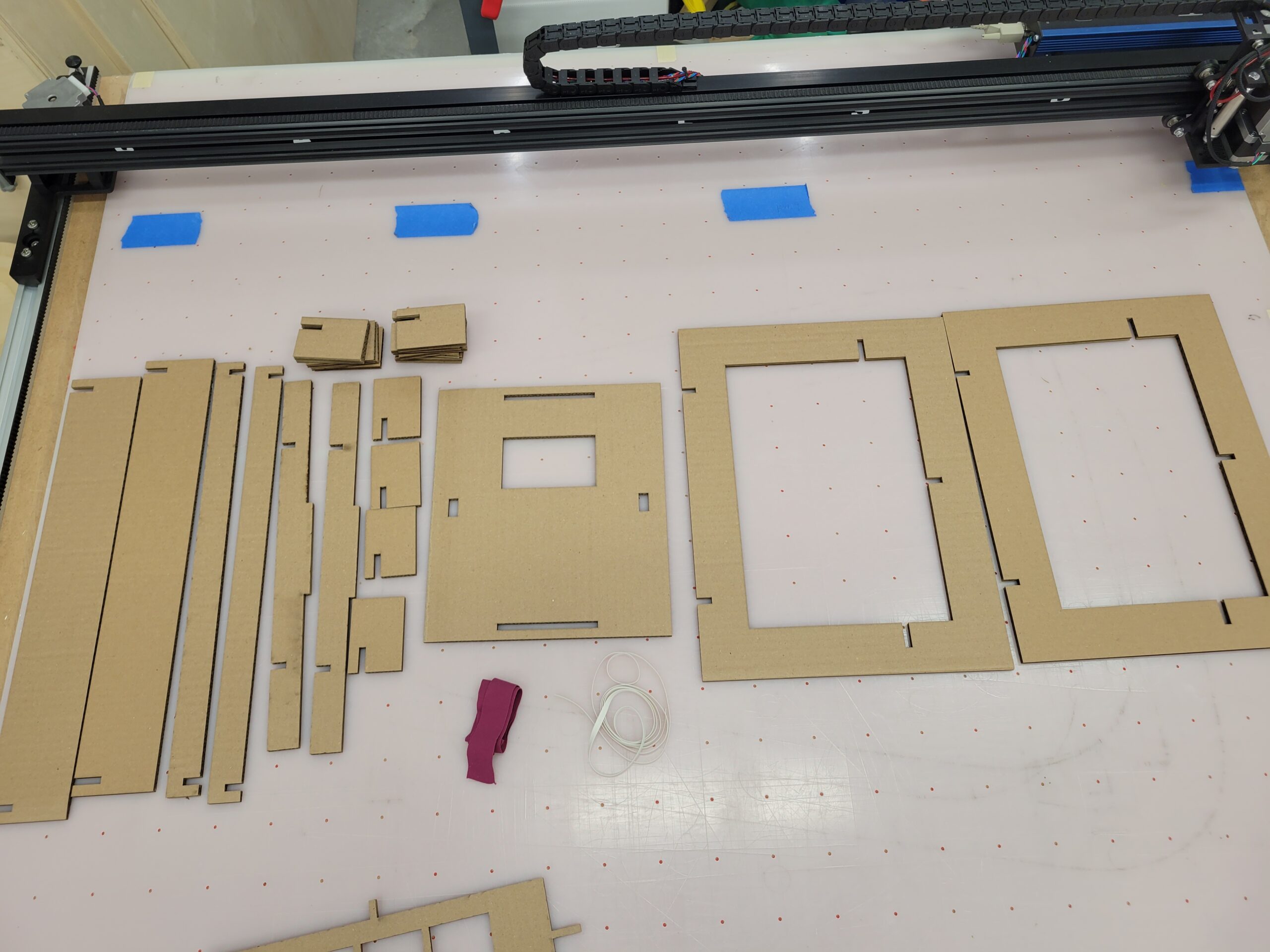

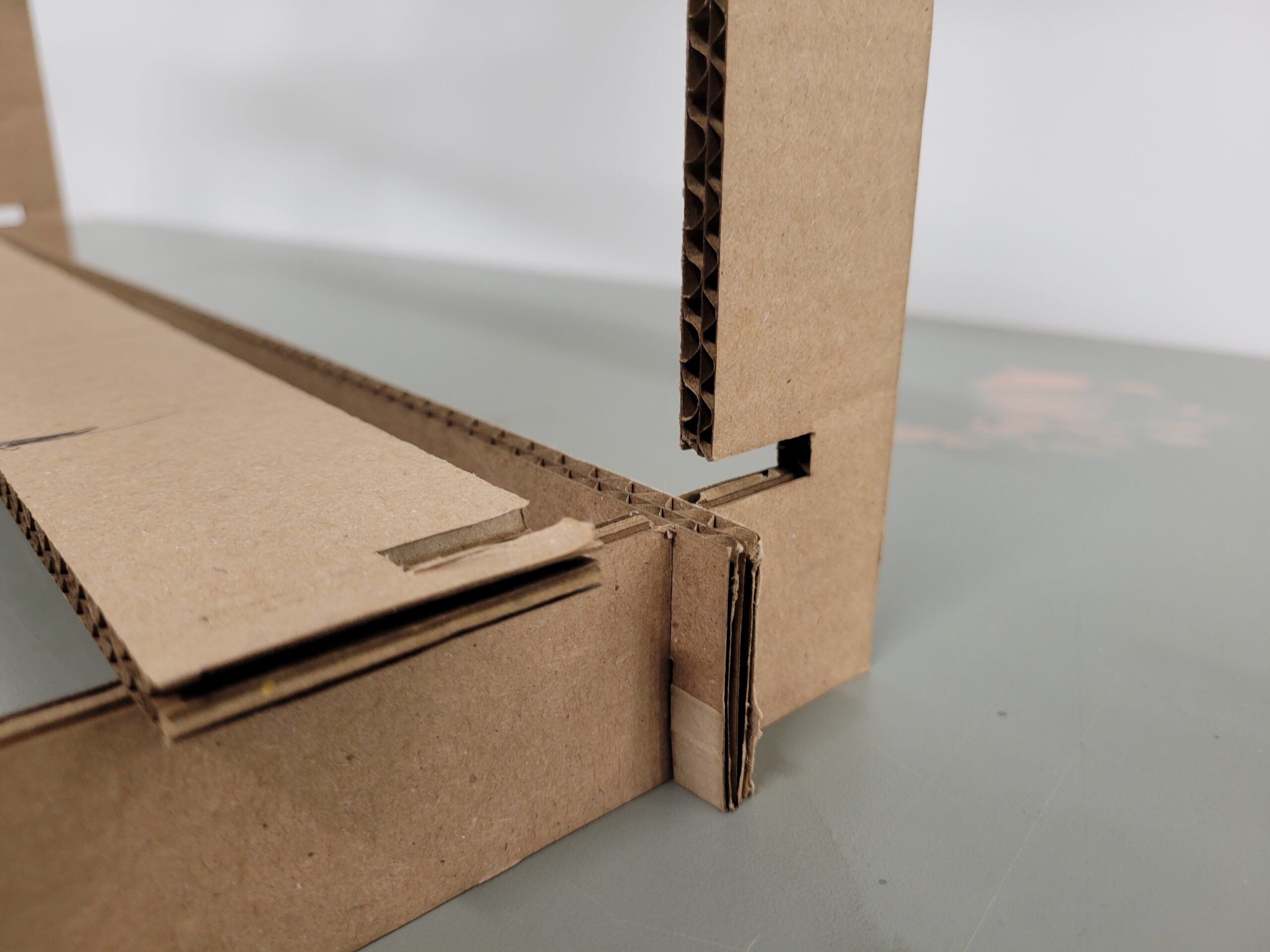

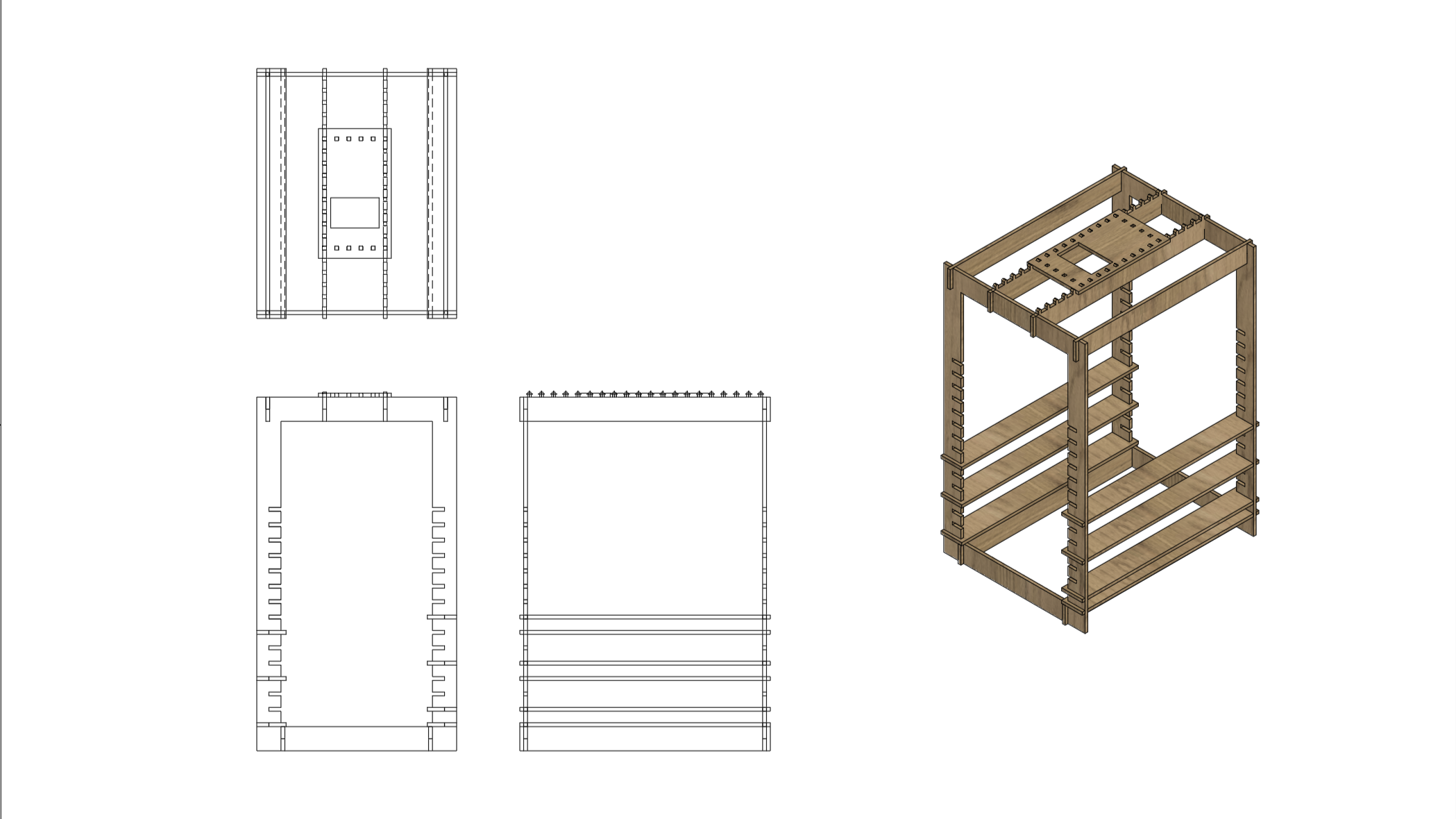

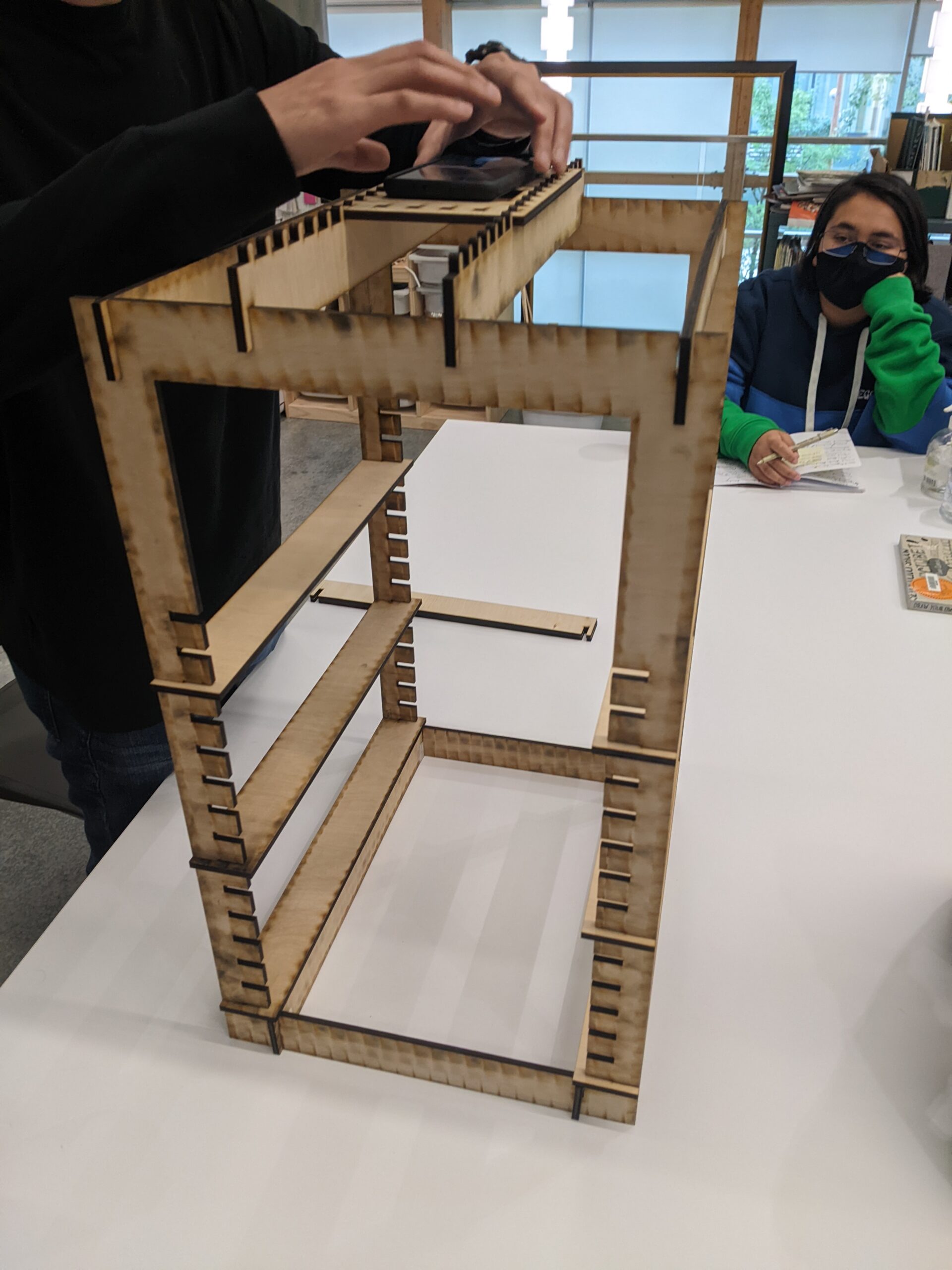

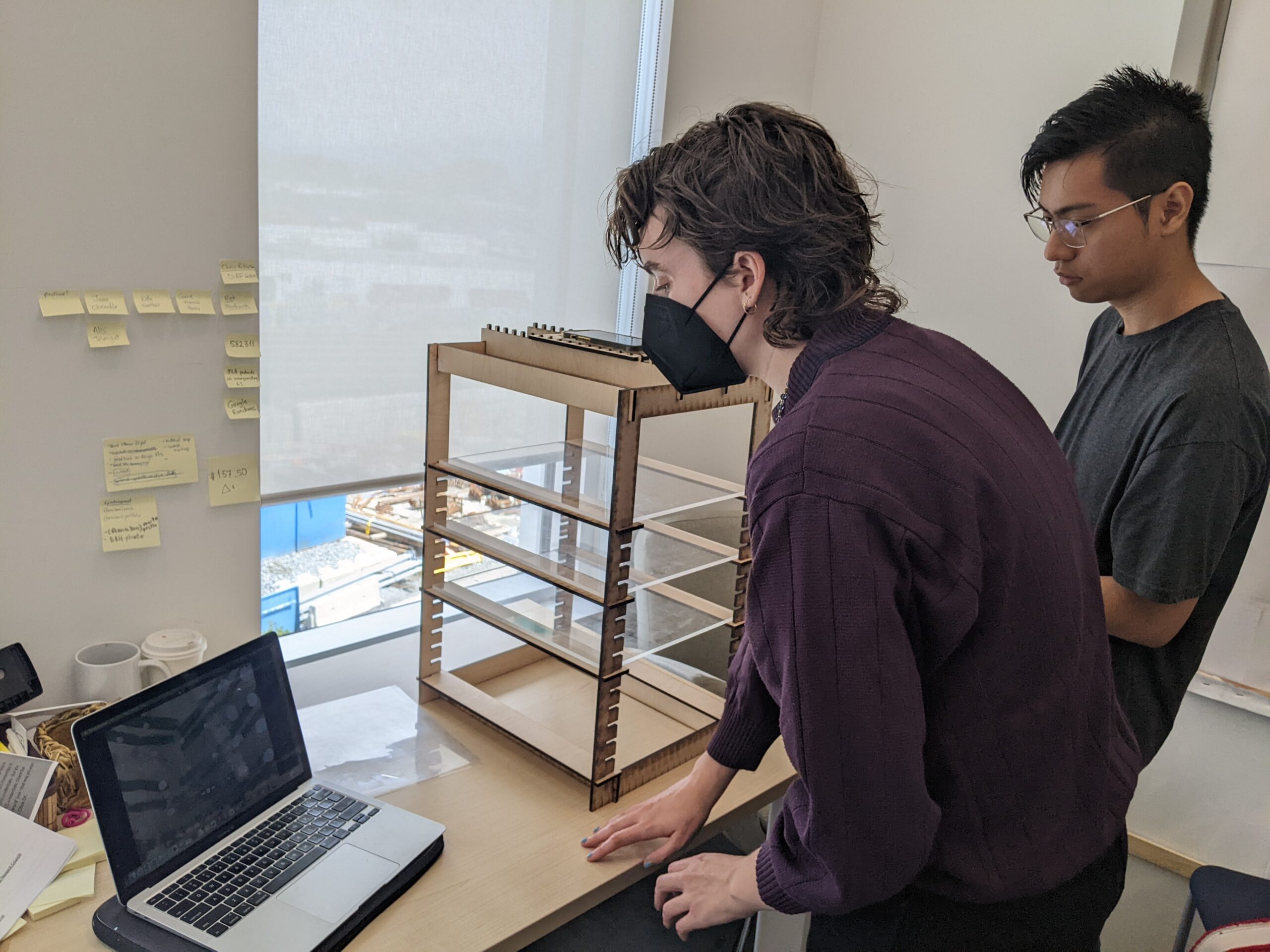

Working with the Animate Materials Workshop team, I developed four prototypes (two cardboard, two plywood), which were then user-tested, reviewed, and modified based on feedback at each stage.

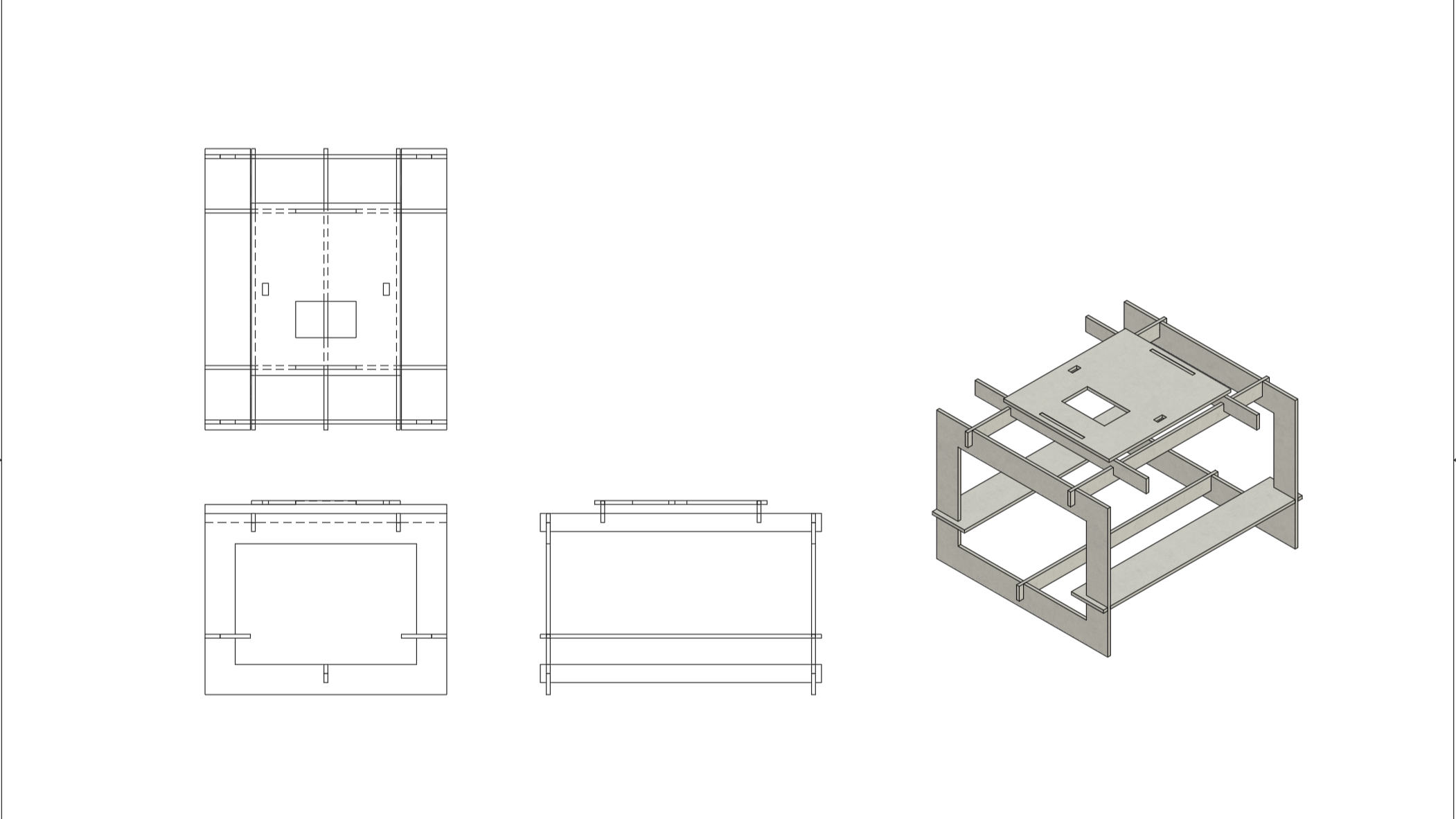

The first two cardboard prototypes established the basic structure, including the frame, braces, and a single beam for each glass plane.

Feedback on these initial designs led to three key modifications:

Minimizing unnecessary parts to reduce bulk and simplify the stand.

Adding the ability to readjust the glass planes for flexible shooting distances.

Integrating a top layer capable of holding and flexibly adjusting a cellphone or light user camera.

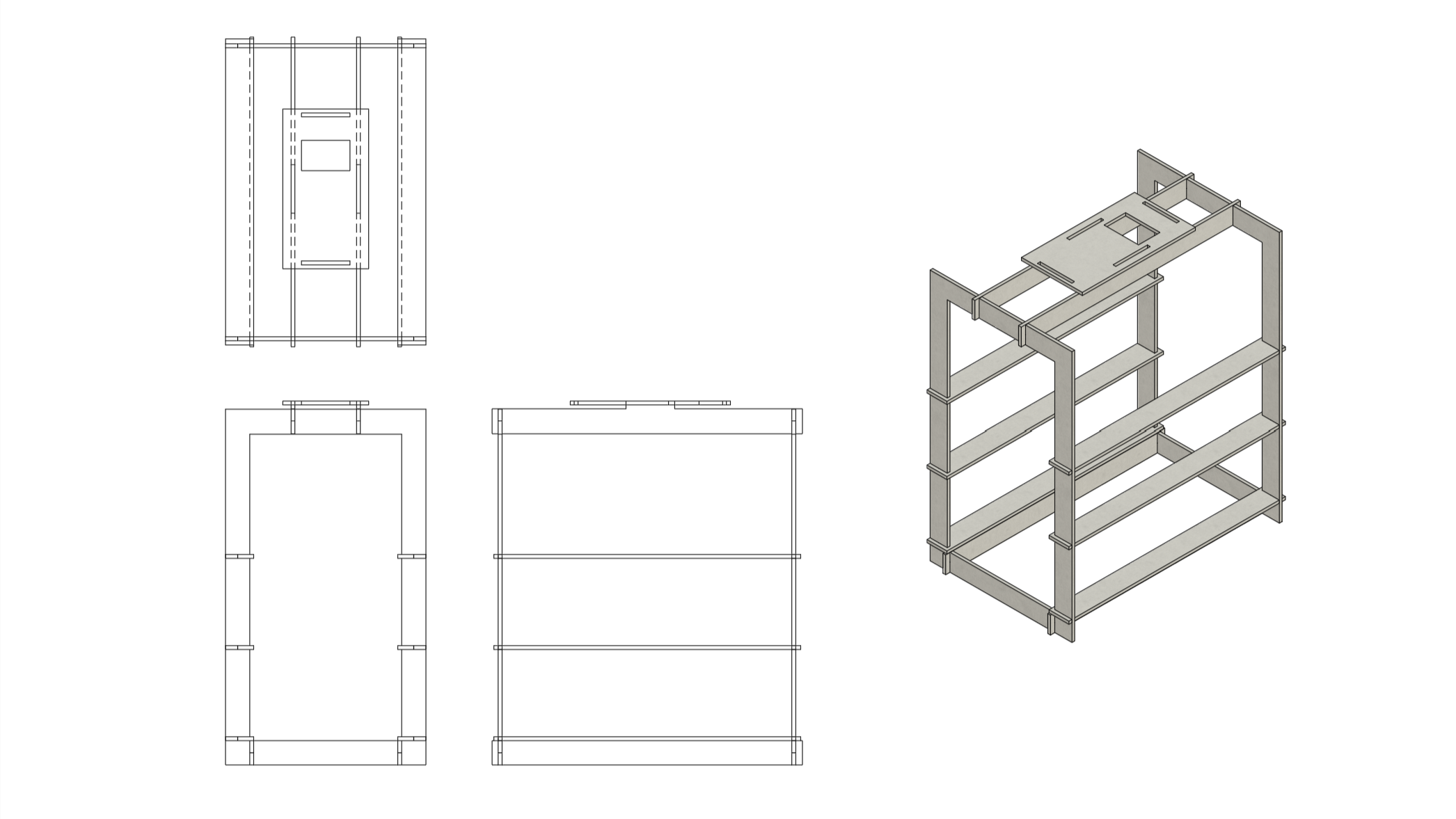

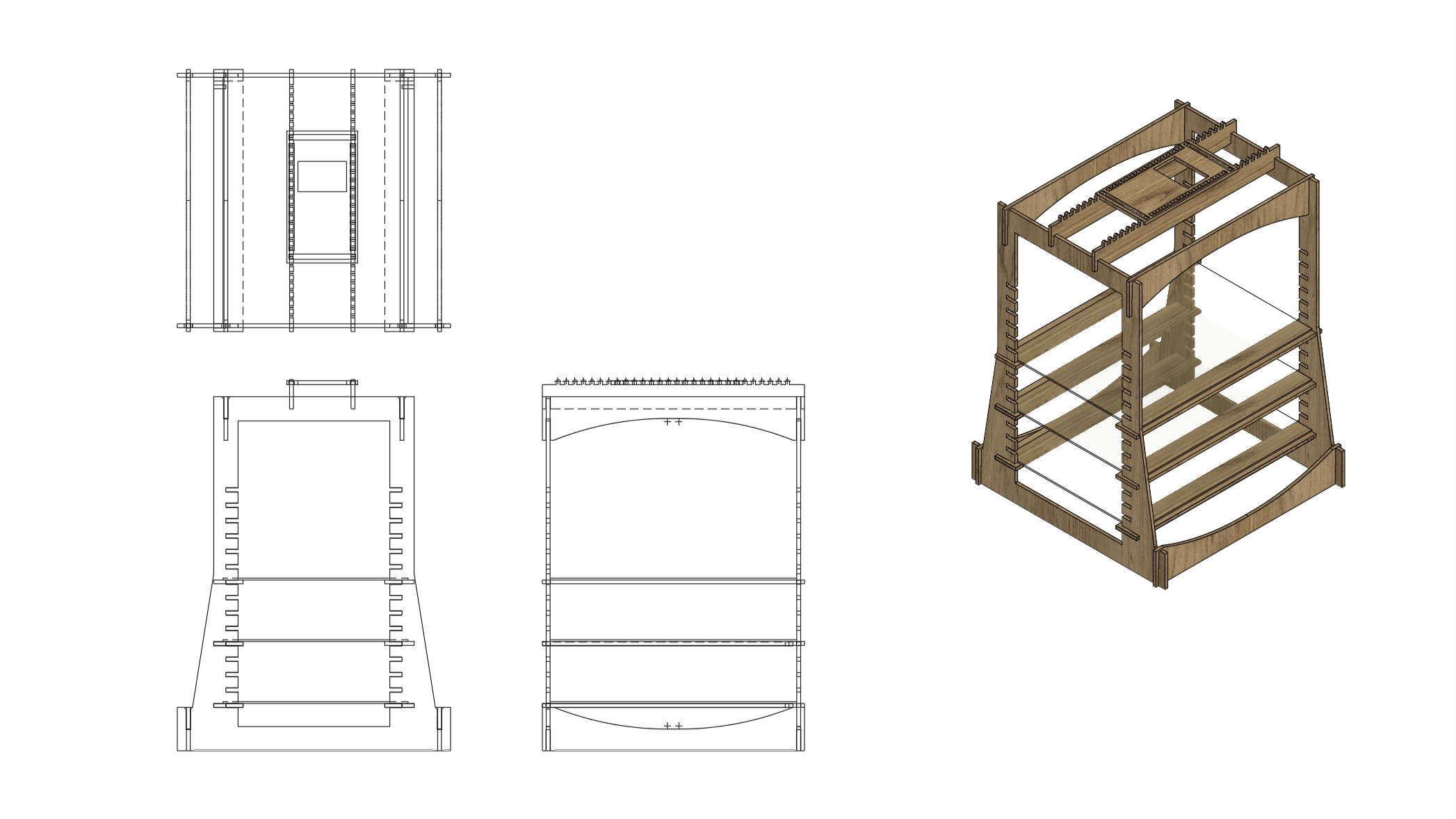

The next plywood prototypes focused on stability and optimizing the fit of the components for easier assembly.

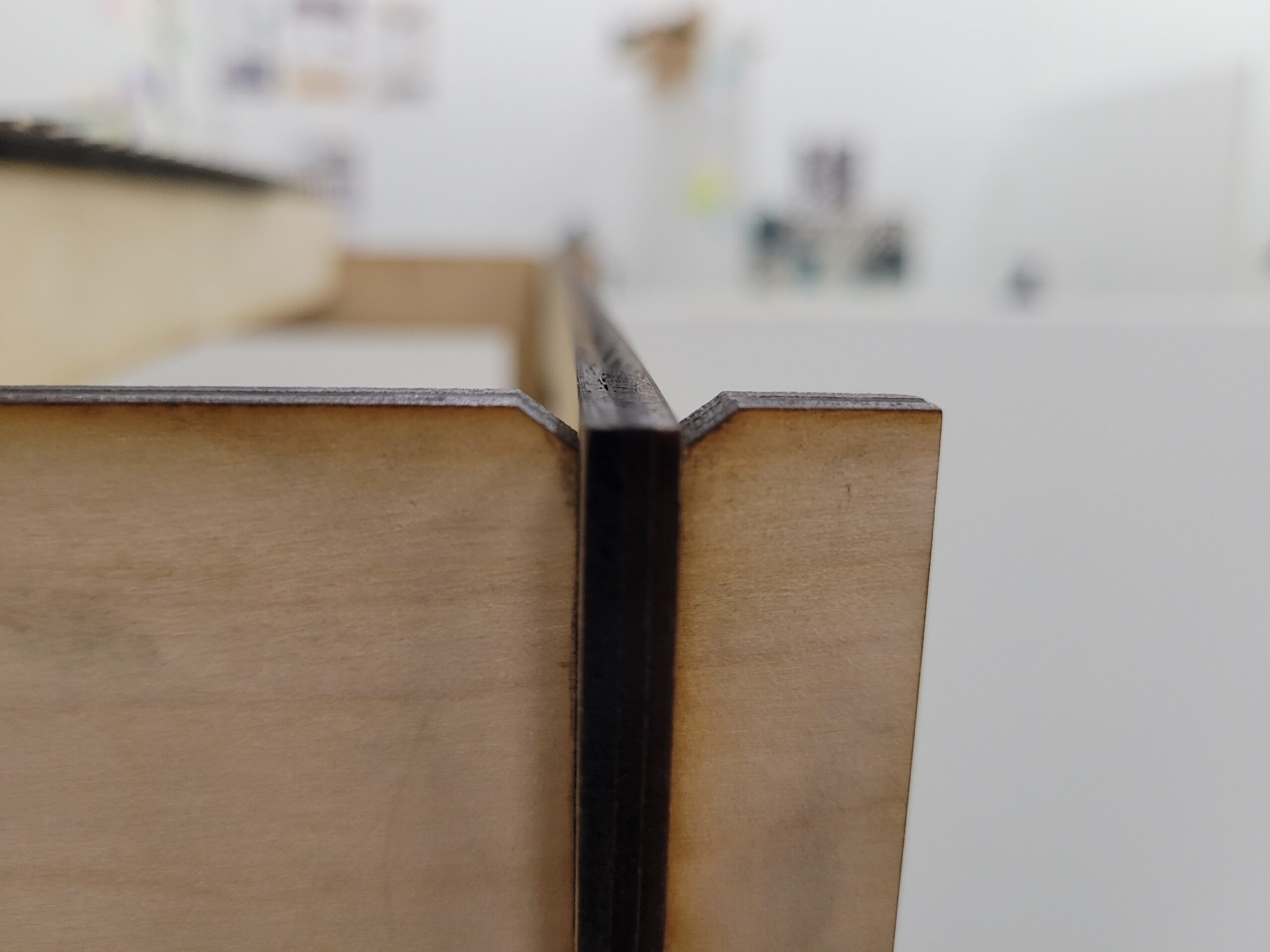

The main design challenges at this stage were addressing stability—a common trade-off for a sleek profile—and improving the loose tolerance of the joinery. To solve this, the team added support braces to the top corners and created a wider, tapered base.

This stage also refined the stand's functionality:

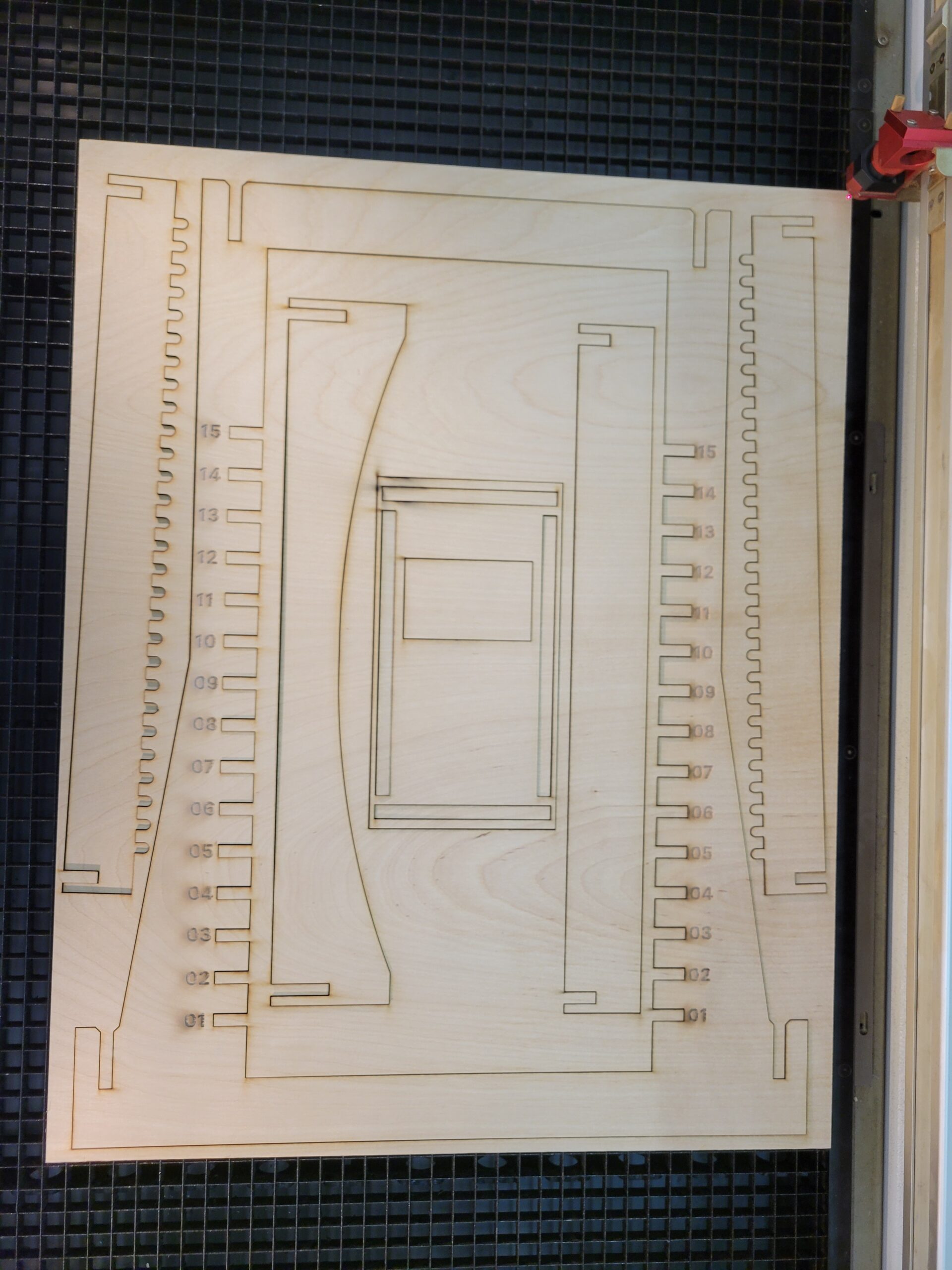

- Versatile Layering: A set of beams with fifteen numbered slots was added, allowing for precise and flexible height adjustments of the glass planes to ensure they remain level.

- Camera Flexibility: The phone holder was updated to support both portrait and landscape orientations.

Following the successful refinement process, four nimble multiplanes were produced for the workshop, and the final design files were made open-access for public manufacturing.

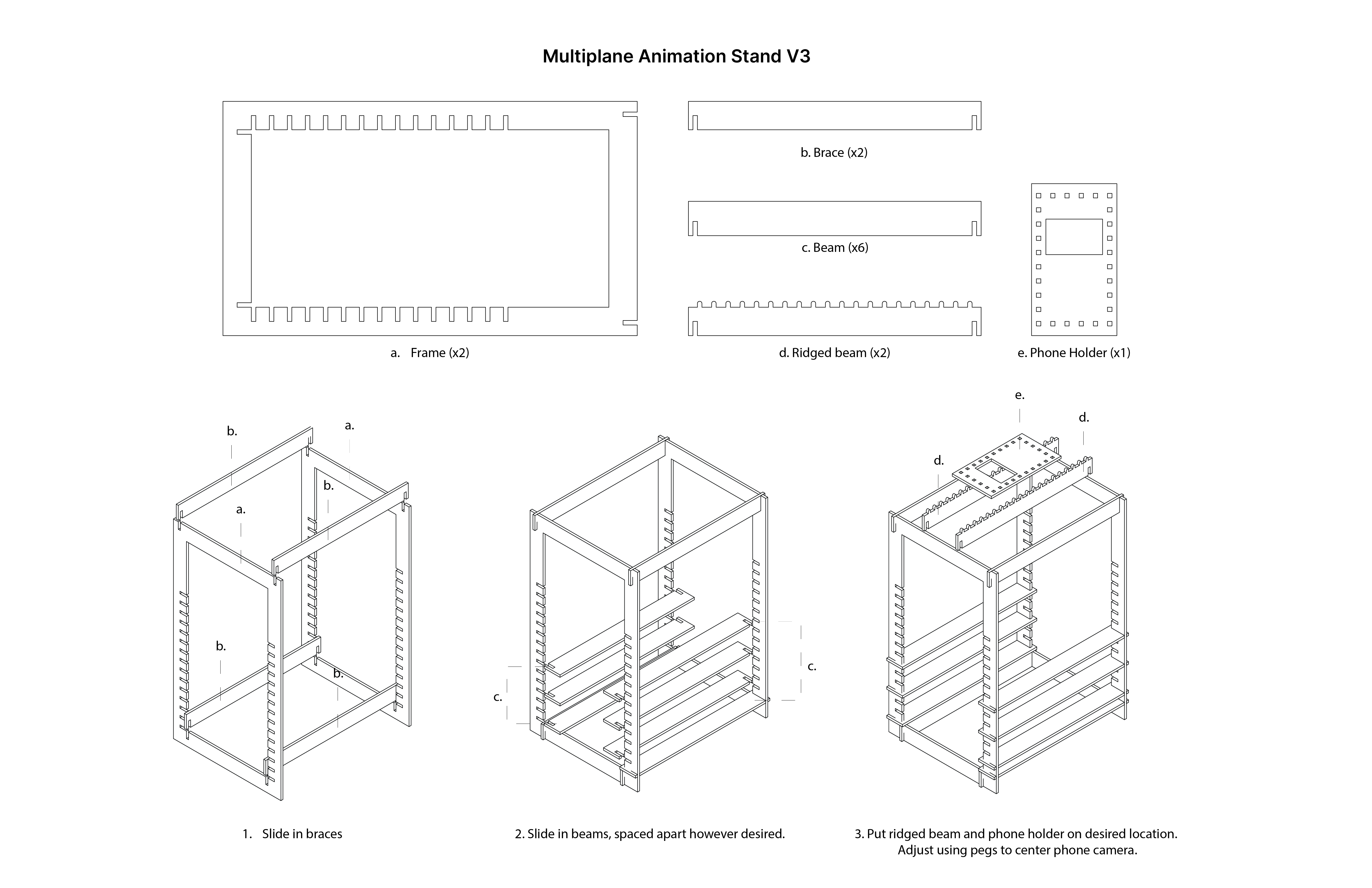

Portable Multiplane Stand Vector File

A set of laser-cutting files for easy fabrication

Assembly Instructions

1 page of easy to follow instructions to produce your own multiplane stand.

Copyright © 2026 Erik Asia. All Rights Reserved.